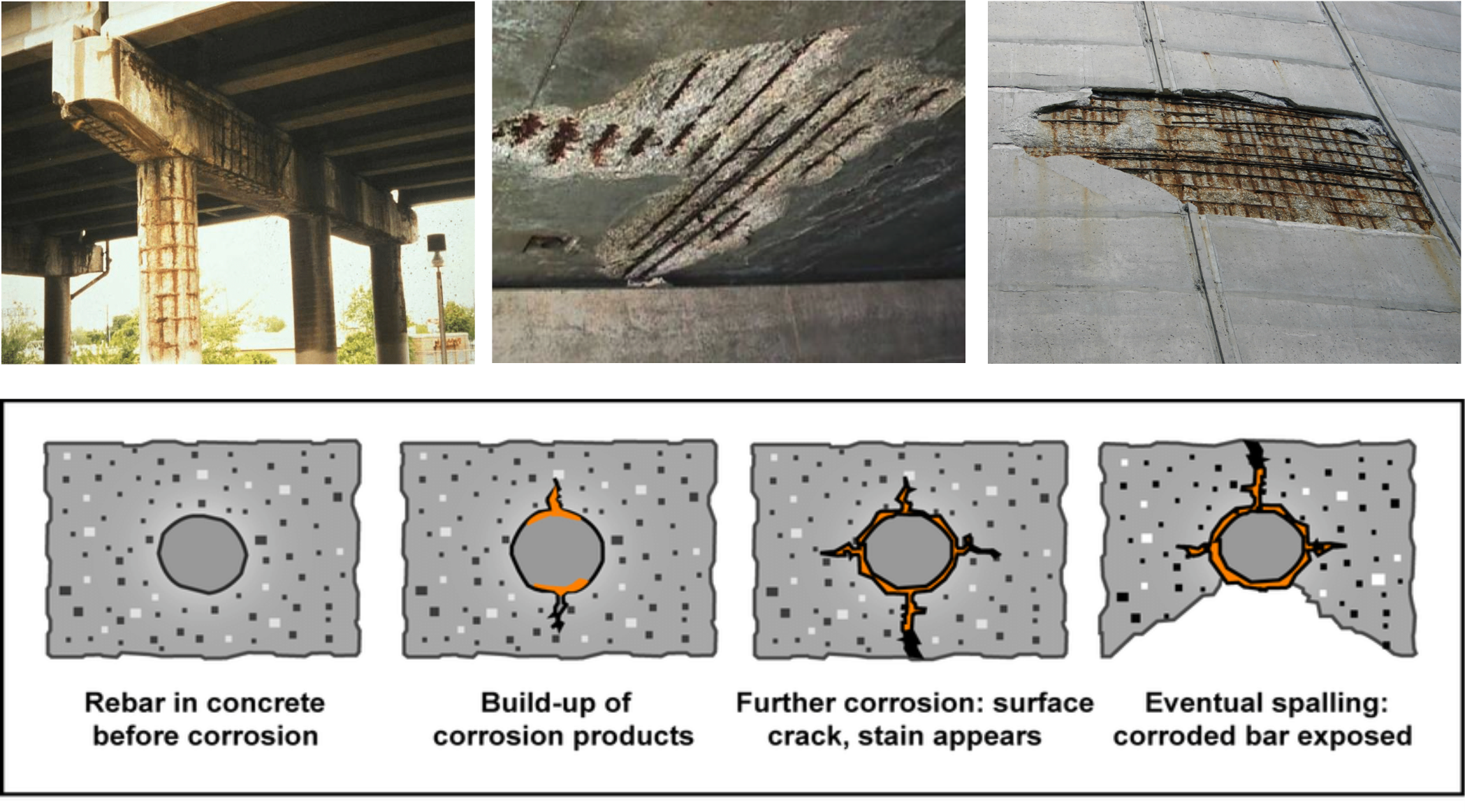

CORROSION PROBLEM IN CONCRETE

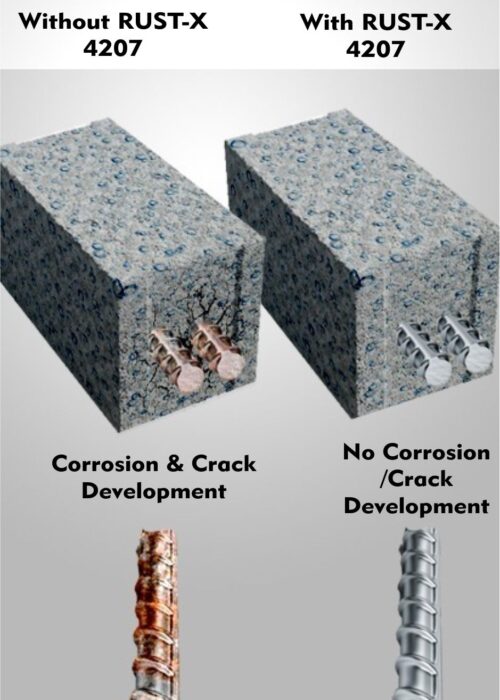

Corrosion in rebar is the most common cause of failure in buildings, bridges, tunnels & structures. RUST-X CCI’s are effective in increasing the service life of the concrete structures by reducing the corrosion rate of rebar in the concrete.In case of the concrete structures, the sand, the salts present in the sand as well as the water in the concrete entering due to porosity play an important role in causing corrosion of the rebar.The rebar forms small electrochemical cells all over the surface due to presence of water and salts which work as electrolyte and cause corrosion.The corrosion rate is higher in aggressive environments in the coastal areas as well as for constructions under water or underground such as bridges or tunnel and lead to cracking and failing of structures.

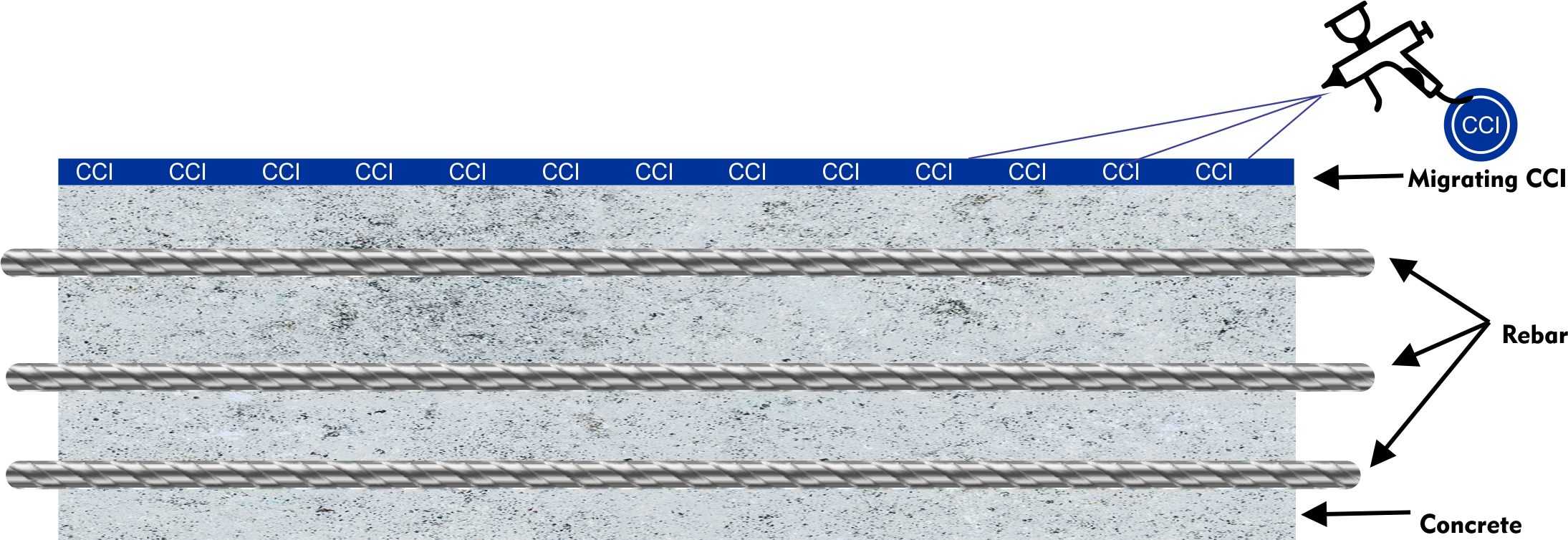

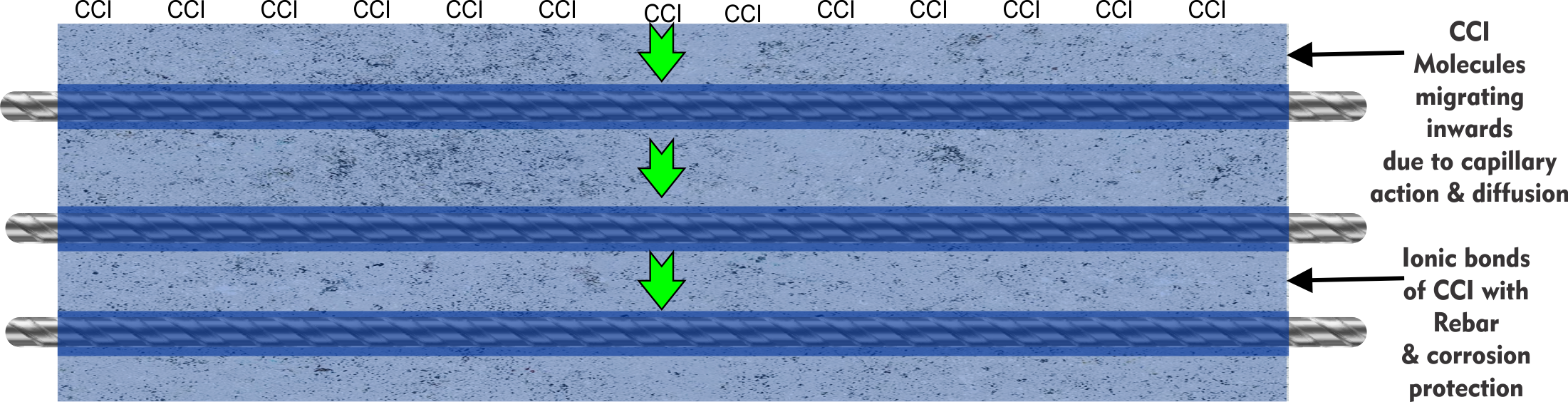

The CCI’s play an important role in drastically reducing the corrosion rate and extending the service life of the constructed bridges, buildings, roadways as well as tunnels.

CCI 4206 Concrete Admixture Additive

for Buildings

Concrete can cause corrosion to rebar due to water during construction as well as its natural hygroscopicity and water retention.The CCI 4206 can be mixed at 1% with concrete to provide excellent corrosion inhibitory effect. The presence of the CCI 4206 molecules within the concrete make it highly corrosion inhibiting reducing the oxidation rate by 80-90% and hence increasing the life of the building from 5 – 10 times. The crack propagation in concrete is drastically reduced.

The effect of corrosion inhibition is highly beneficial in coastal areas, rainy places where buildings remain damp all the time as well as in places having high humidity or having high salt content in soil and sand.

The dosage recommended is 10 kg per m3 of the admixture for normal environments and 20 kg/m3 for aggressive environments.The addition of the CCI 4206 does not have any detrimental effect on the setting time or compressive strength of the cement.

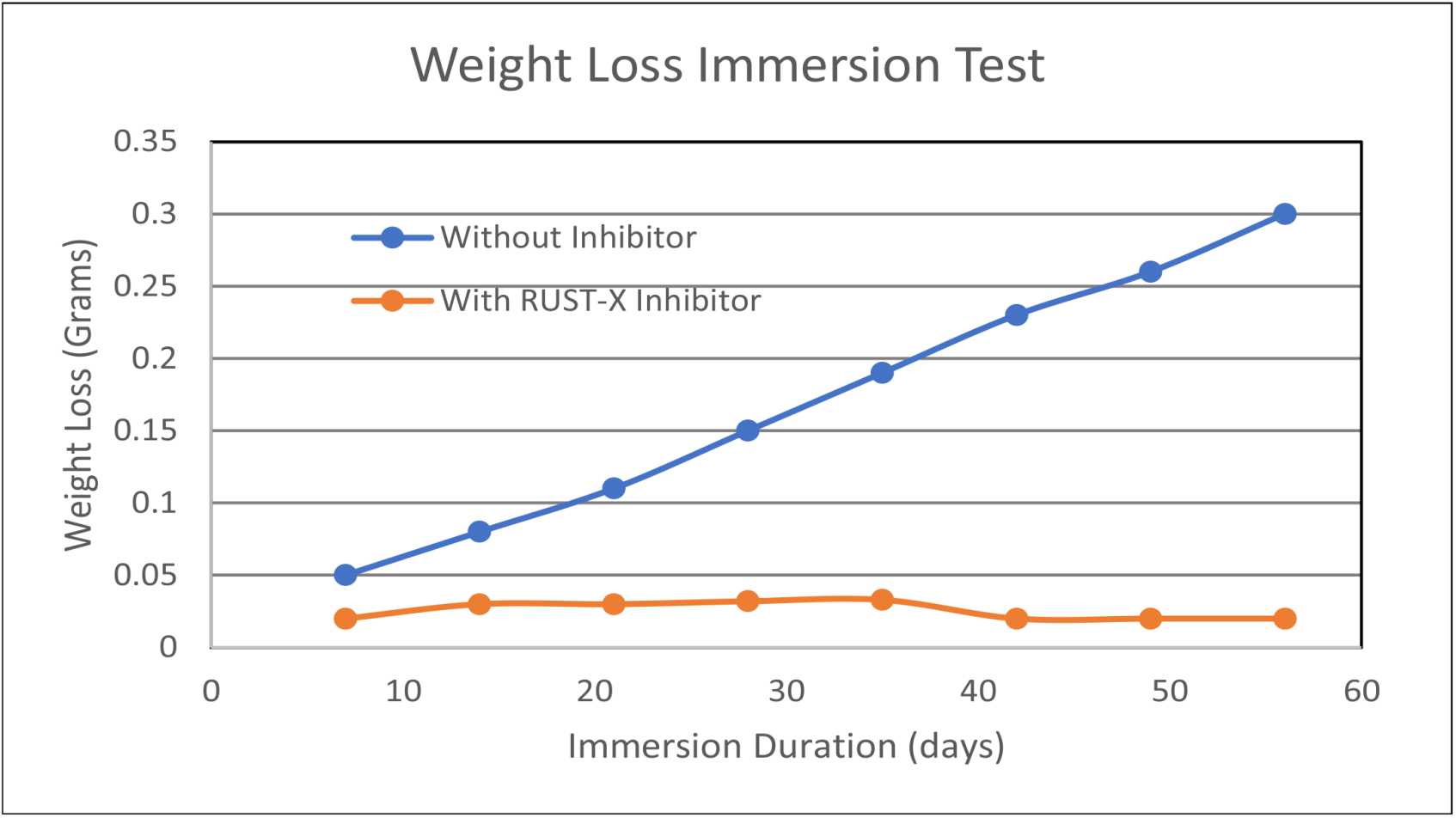

Figure 1 shows the metal weight loss or corrosion loss of steel rebar in salt water during an immersion test in salt water

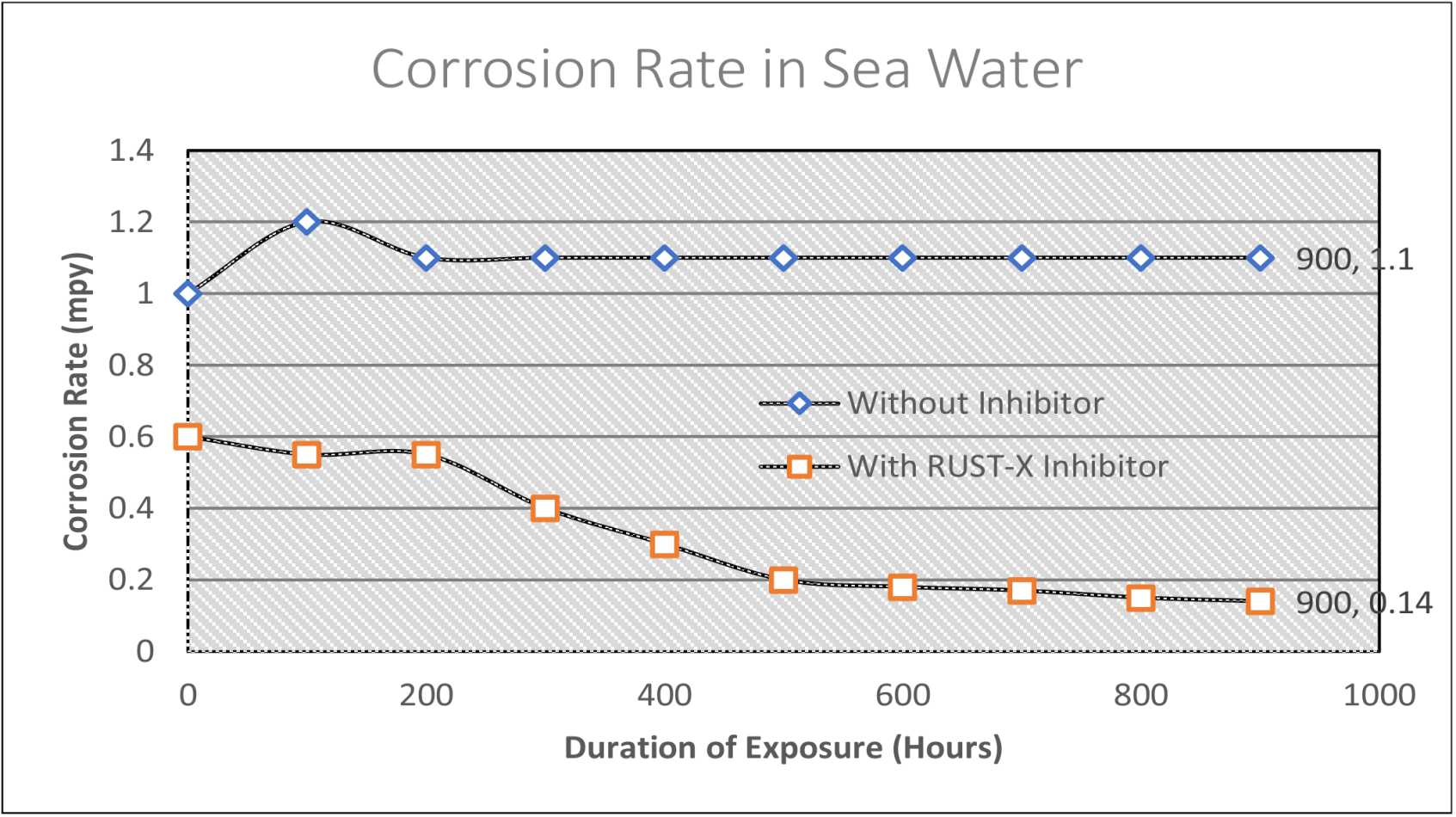

Figure 2 shows the corrosion rate of steel rebar in salt water.