Rust Removers & Rust Converters

Rust Converters

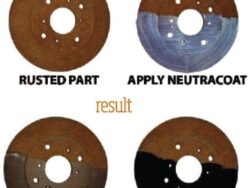

Neutracoat Rust Converter is a powerful oxidation converter designed for use on various steels, iron, cast iron and copper, metals & aluminum.

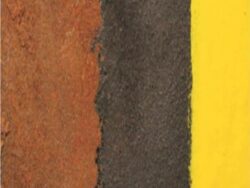

Neutracoat Rust Converter is a aqueous solution designed to convert rust and oxidation safely and economically. The biggest advantage is that the components do not get rusty again after removing from solution which is case in Acidic Rust removers and forms black inactive layer on the metal surface which can then be painted for longer life.

Rust Remover

Rusting is the biggest evil for the steel or automotive component industry. Hi-Tech Internationals proprietary rust converters, help in the recovery of metal by converting the rust back to steel. Rusted components can be retained back by the process of rust removers, then neutralization and finally applying rust preventive oils.

RUST REMOVER 500 is a liquid acid-based product primarily designed to simultaneously clean and remove rust from steel and iron parts. It is single component modified acid with different additive base rust removal. It has uses for removal of rust and prepares the substrate for painting.

FAQ’S

Does rust converter actually work?

Rust converter is a coating that will convert heavy rusted areas into a protective polymeric coating with little prep.

Neutracoat Rust Converter easily works in the nooks and crannies and all the other wetted areas eliminating the need for mechanical removal.

NeutraCoat Rust Converter will save your money and time by eliminating the need for time –consuming sanding and grinding operations, not to mention the coast of labor associated with these operations.

How is Rust Converter applied?

Take the rusted part and dip it in the solution for a few minutes or apply with paint brush. Flash rusted parts may take up to 3 minutes – 30 minutes and very highly rusted components may take up to few hours.

The product does not get tarnished as in acid solutions and can be left within solutions for up to days.

Other methods may be used such as mist spraying, electrostatic spraying, brushing, automatic conveyor spray or dip process pray. It is important that the complete surface of the component is coated with the neutracoat solution.

What is Rust Remover ?

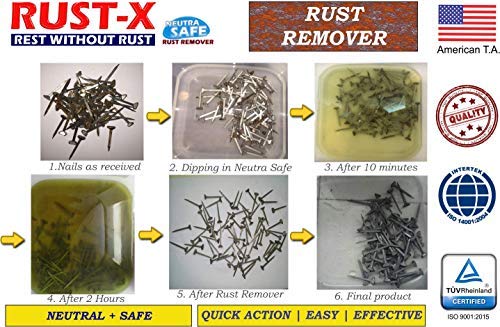

RUST REMOVER 500 is a liquid acid-based product primarily designed to simultaneously clean and remove rust from steel and iron parts. It is single component modified acid with different additive base rust removal. It has uses for removal of rust and prepares the substrate for painting.

Quickly removes rust and corrosion from steel, cast iron and other ferrous metals. Does not harm nonferrous metals such as aluminum, copper or brass and is also safe on rubber and plastics. Quickly penetrates into crevices and metal pores due to special wetting agents so that all rust and corrosion is reached.

How Rust Remover Works?

Dipping by far is the best method for establishing an even layer on the component. Other methods may be used such as mist spraying, electrostatic spraying, brushing, automatic conveyor spray or dip process pray. It is important that the complete surface of the component is coated with the RR 500.

Use of gloves while handling the components as well as immediate packaging is important. In case the components carry cutting oils or water from previous processes, dewatering with CL005 is recommended.

Showing all 2 results