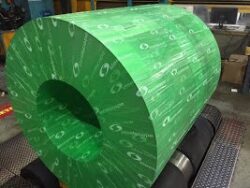

Anti-Corrosive VCI Packaging Solutions

Rust-X is one of the leading VCI Film manufacturer & supplier in India and worldwide. We are expert in VCI technology. Integrated combinations of VCI Packaging protection systems, such as VCI corrosion protection with acid-gas scavenger and anti-static (ESD) are available to provide the best result.

Rust-X application engineers can recommend and implement the best corrosion management system from our large selection of stock products or create a cost-effective custom solution. Packaging and corrosion prevention become one step solution when you use Rust-X VCI packaging products.

FAQs

What does VCI stand for?

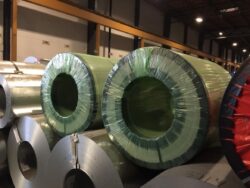

The term “VCI” stands for Volatile Corrosion Inhibitor. Metal parts can corrode during storage & transportation. Corrosion prevention oils & greases were used to prevent corrosion, however, it required cleaning before the delivery to the customers.

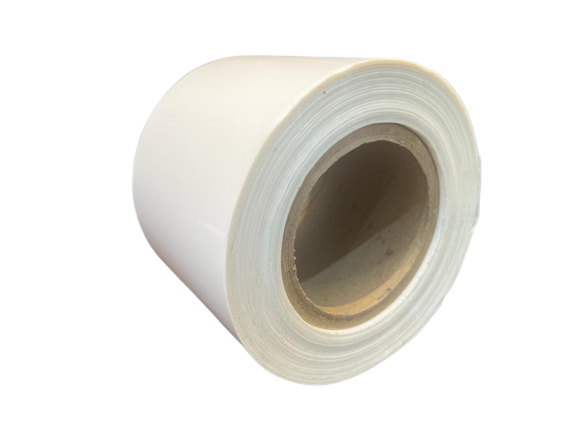

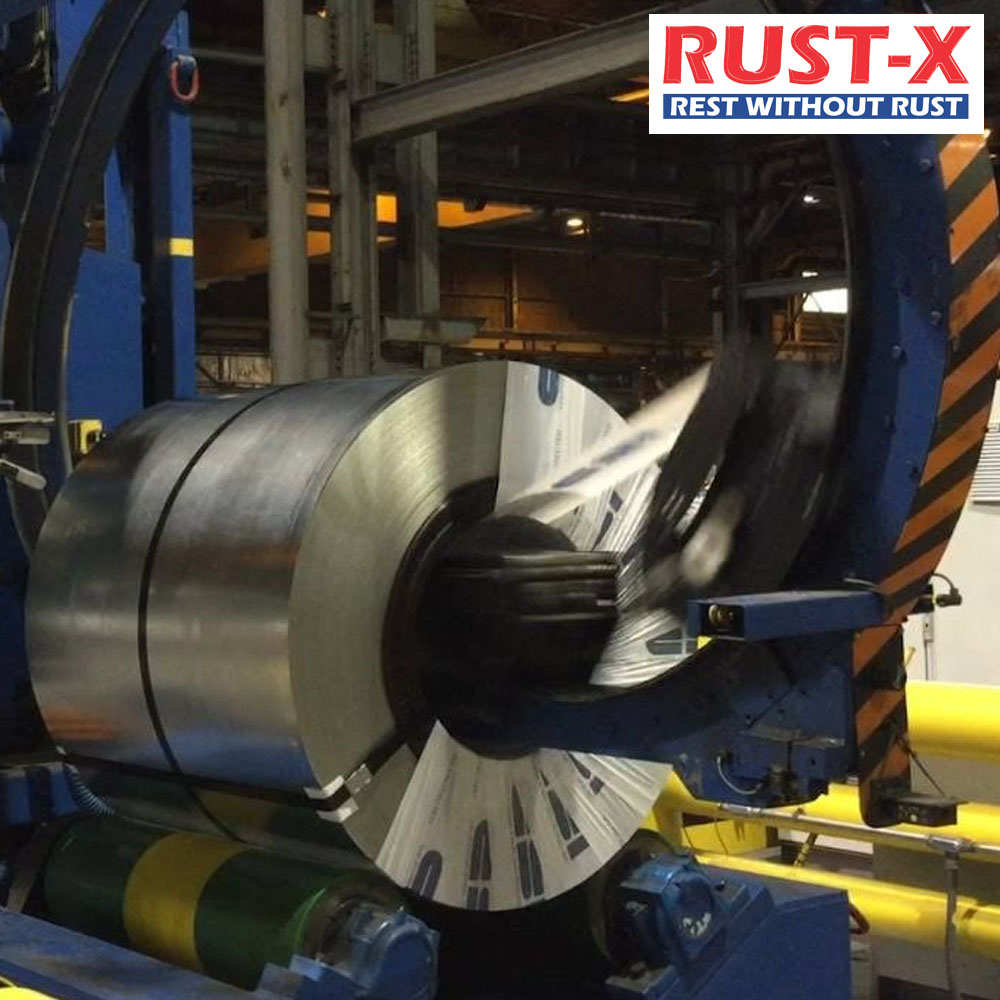

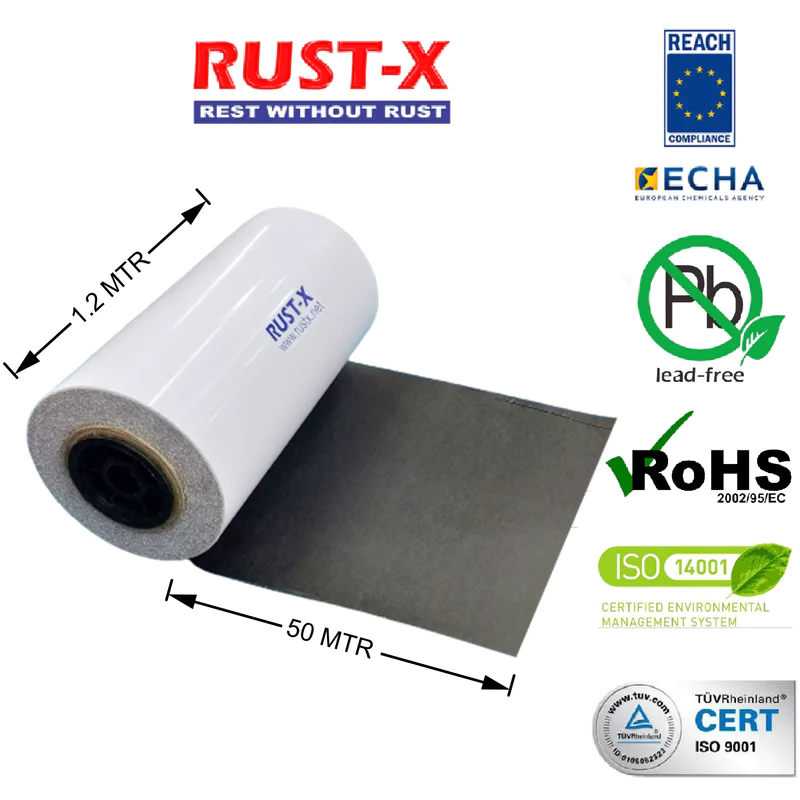

In recent years, volatile corrosion inhibitors (VCI) are available in paper, films & rolls form which provides a clean and dry method for corrosion prevention.

What is VCI Packaging?

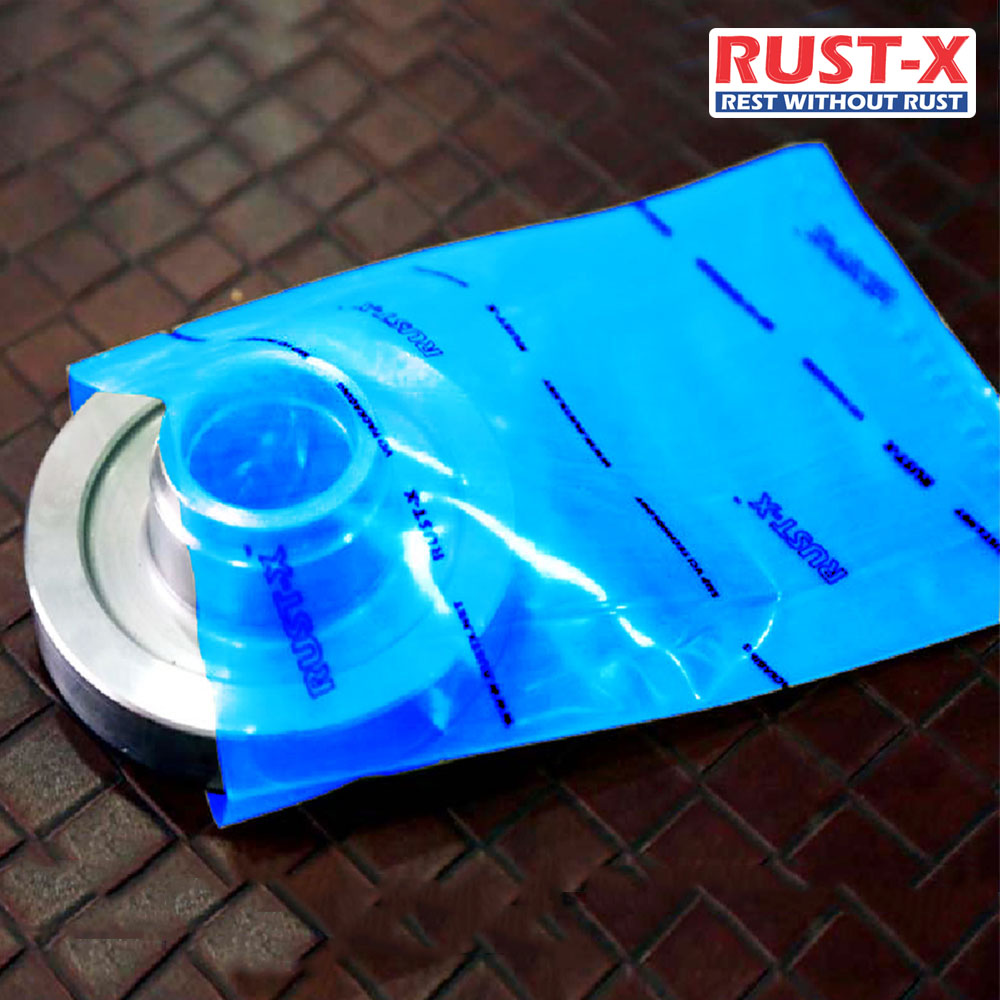

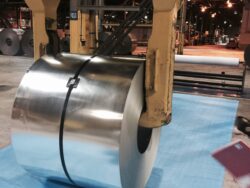

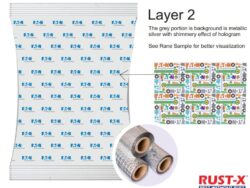

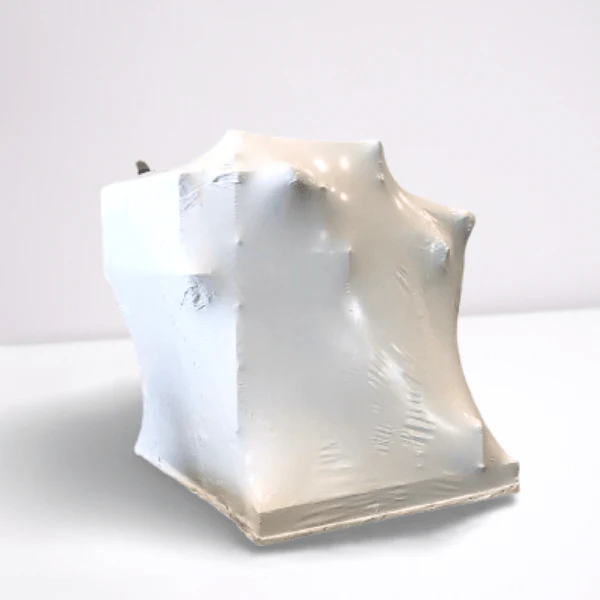

Volatile Corrosion Inhibitors (VCI) Packaging is a packaging film which volatilizes the compounds to form protective layer around metal surfaces. VCI Packaging prevents salt, dirt & other corrosive particles to come in contact with the metal parts.

How does Rust-X VCI Packaging Work?

Rust—X VCI Packaging materials are available as VCI Paper, VCI rolls, VCI plastics, VCI emitters etc. VCI Packaging are rust inhibitor solutions for packaging, transporting and storing metal parts. Rust-X VCI Films are manufactured using the most advanced technology to protect any metal.

Rust-X VCI works by:

- Evaporation & deactivation of moisture

- Multi-molecular film on the metal

- Altering the pH

- Passivating the electron flow

Rust-X Packaging Solutions

Showing all 20 results