What is VCI Volatility ?

What is VCI Volatility ?

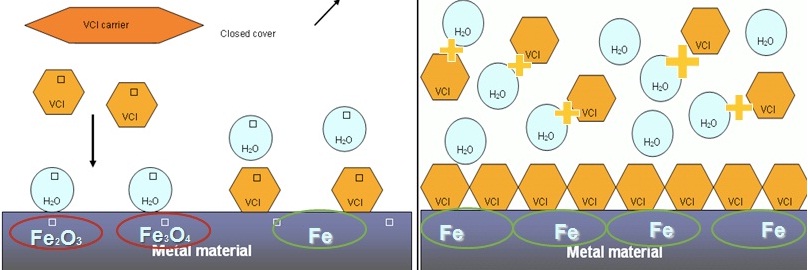

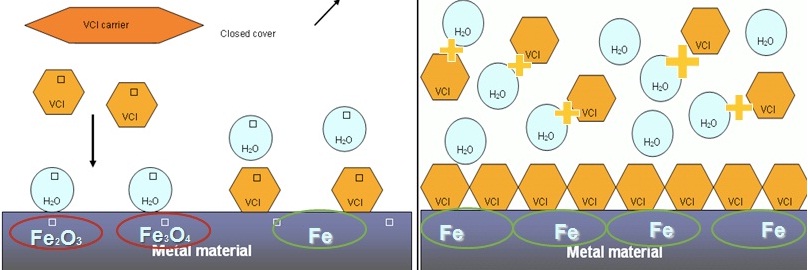

The volatility of a VCI (Volatile Corrosion Inhibitor) refers to its ability to release molecules or chemicals that can prevent or reduce corrosion on metal surfaces. VCIs are designed to volatilize or release their protective chemicals into the air and create a protective atmosphere around the metal surface, thereby preventing or reducing corrosion.

The volatility of a VCI is dependent on several factors, including the chemical composition of the VCI ,the packaging material, the storage conditions, and the size of the enclosed area. Generally, the volatility of a VCI can vary from a few days to several months or even years. The rate of volatilization is affected by factors such as temperature, humidity, and air flow in the storage environment.

VCIs are designed to provide long-term protection to metal surfaces during storage or transport. The duration of protection varies depending on the VCI product, storage conditions, and the type of metal being protected. It is essential to follow the manufacturer’s instructions for the specific VCI product being used to ensure optimal performance and protection.

How long does VCI take to volatilise?

The time it takes for VCI (Vapor Corrosion Inhibitor)to volatilize or release its corrosion-inhibiting vapor depends on various factors, such as the type and thickness of the VCI material, temperature, humidity, and the size and complexity of the metal part being protected.

Generally, VCI packaging is designed to release its vapor quickly, within hours or days, once it is exposed to air. The vapor can then form a protective layer on the surface of the metal and continue to provide corrosion protection for several months or even years, depending on the packaging and storage conditions.

It is important to note that VCI packaging should be stored in a dry, cool place and kept sealed until it is ready to be used. Once the VCI packaging is opened, the vapor will begin to release, and the packaging should be used as soon as possible to ensure optimal corrosion protection.